Masks and Respirators With Exhalation Valves Don't Protect Others

Note: This article was written during the Covid 19 pandemic, but applies to any situation where masks or facecoverings are worn are source control (to limit disease transmission or contamination from the wearer's exhaled particles).

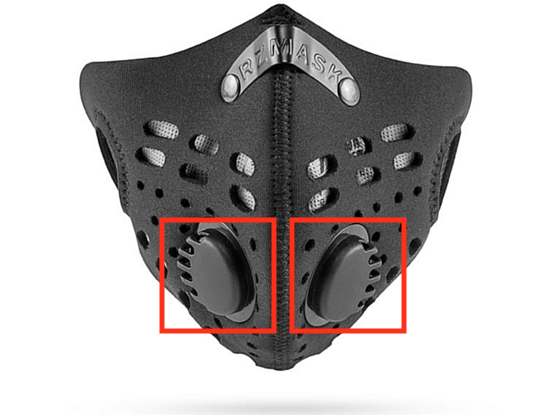

Wearing masks in public, or when working with other people, helps prevent particles and droplets from the mask wearer's mouth and nose from infecting other people. Masks with an exhalation valve do not provide protection to other people, as exhalations go right out without being filtered or significantly slowed. The exhalation valve is like a vent that flaps open every time the user breathes out; It makes it more comfortable for the wearer, but exposes those around them to contamination.

Here are a few examples of exhalation valves on different styles of masks:

We should think of masks in two different categories:

-Personal protective equipment (PPE). Masks required for the safety of the persons wearing them, to protect them from some hazard (whether it's biohazards, concrete dust, paint vapors, etc). These require annual fit testing and training, and if selected and worn correctly, keep contaminants out of the user's lungs.

-Community protective equipment (CPE). Masks, usually reusable fabric or disposable medical masks, worn to reduce the risk of getting other people sick by slowing and capturing germs from exhalations, sneezes, coughing, speaking, etc. If there's a giant opening in the front of the mask that flaps open every time the wearer exhales, the community protective effect of the mask is compromised.

Respirators with an exhalation valve can be an excellent choice for personal protective equipment if the wearer is properly trained and fit tested. However, if the exhalation valve is not properly covered, this irresponsibly exposes others to danger if the mask wearer is infected, but not symptomatic (which is very common with Covid 19). This is an issue for all workplaces, but particularly in a healthcare setting, where a provider wearing a valved mask will be in close proximity to a patient to provide care and may infect them.

Additional suggestions that may apply to certain workplaces:

- If your workplace is open to clients or the general public, many people are uninformed about this issue with exhalation valves and may be wearing these types of masks. If possible, have some cheap medical or fabric masks available for them to wear instead, or layer over their existing mask to cover the exhalation valve.

- For industrial and construction workplaces with jobs that ordinarily require respirator use, where everyone in the work area is wearing a particulate respirator they have been trained on and fit tested for, it's probably not necessary to cover vents. But in areas where some people may not have masks, or only have fabric masks, or other looser fitting masks they haven't been fit tested for, vented masks need to be covered to protect others in the area from potentially getting sick.

- For companies that have or are considering prohibiting employees from wearing valved masks (when they are wearing personal masks on a voluntary basis, not due to a specific workplace hazard), this policy should be reconsidered. Vented masks are usually better designed in terms of the way they fit and the protection they provide for the wearer. However, vented masks definitely need to be covered in some way with an unvented mask, filter material or tightly woven fabric.