RESEARCH ARTICLES

Information on workplace safety and emergency response topics from the team at Safewest.

Respirator facepieces, cartridges, and filters are routinely counterfeited. Most buyers cannot verify whether what they received is authentic, and the marketplace isn’t set up to ensure authenticity. Respiratory protection is especially vulnerable to counterfeits because the most safety-critical functions cannot be confirmed by visual inspection. A trained eye might catch subtle tells, inconsistent molding marks, off-color materials, or printing and labeling errors. But appearance does not verify performance. You cannot reliably determine by sight whether a cartridge contains the correct sorbent, whether a particulate filter actually meets its required performance rating, or whether facepiece materials and components will maintain a stable seal under real-world conditions over time. A respirator’s protective performance is driven by materials and manufacturing tolerances, including the composition and consistency of the facepiece elastomer, the integrity of the lens and frame, strap and buckle hardware strength and elasticity, sealing surface geometry, and the design and quality of inhalation and exhalation valves. Small substitutions or dimensional changes can materially affect fit, seal reliability, and durability. For filter cartridges, protection depends on the correct filter media or sorbent formulation, a reliable seal between the cartridge and the facepiece, and internal construction that controls airflow distribution and loading. Substitutions in media, sorbent, adhesives, gaskets, or internal geometry can reduce protection immediately and may lead to premature chemical breakthrough or inadequate filtration performance. Because these performance characteristics cannot be confirmed by inspection, the only practical safeguard is a verifiable supply chain. When chain of custody is unclear, the buyer has no defensible basis to trust authenticity, certification, or performance. The risk is highest when products come from online marketplaces like Amazon, especially third-party sellers, liquidators, or “new in box” resellers with no traceable sourcing. Commingled inventory practices, where “identical” products from different sellers can be pooled in warehouses, further increase the risk of counterfeit products entering the supply chain. Despite specifically advising clients not to purchase PPE, especially respirators, from Amazon, eBay, or similar online marketplaces, we are seeing this guidance disregarded. We arrive to fit test respirators that show subtle differences from the authentic 3M products we supply. In multiple cases, those units are ultimately confirmed as counterfeits purchased through the exact sources we advised against. Using price as the primary, or only, selection criterion for a personal protective equipment vendor is irresponsible. The employer owns the consequences of negligence in purchasing. If there’s an exposure incident, an injury, or an audit, “we got it online” or "it had free Prime shipping" is not a defense. Workers notice too. When employees don’t trust the gear, company safety culture quietly collapses. Buy PPE through: - Authorized distributors - Direct from the manufacturer - Established industrial or safety suppliers with traceability

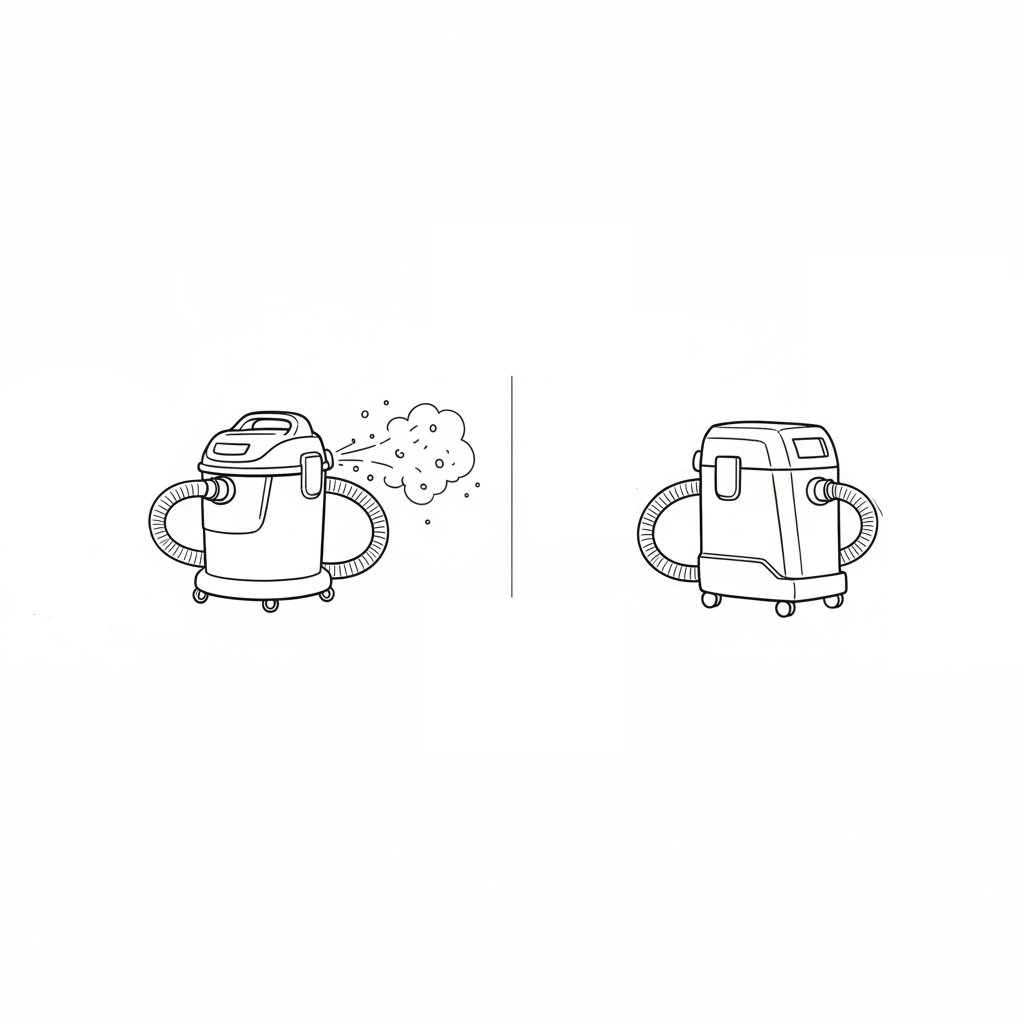

At a glance, a shop vacuum with a HEPA filter and a dedicated HEPA-rated dust extractor might seem to do the same job: collect dust and debris. In reality, the difference between them is substantial, especially for fine particulate control, worker protection, and regulatory compliance. Adding a HEPA filter to a standard shop vacuum improves filtration, but it doesn’t turn the unit into a true HEPA-rated system suitable for hazardous dust. Key takeaway: If you’re collecting fine dust from hazardous materials, use an extractor designed and certified for that purpose. Don’t rely on a shop vac with a retrofit HEPA filter. Here’s why: Most shop vacs leak around seals or bypass fine dust through motor vents, even if they use a HEPA filter. A proper dust extractor is designed from the ground up for fine dust control. All seals, gaskets, and joints are engineered to prevent leakage, and the entire system, not just the filter, is tested to meet HEPA performance. Shop vacs are built for high pulling force (static pressure) to pick up debris, nails, or sawdust through hoses. Dust extractors are designed to steadily move larger volumes of air (airflow) and catch fine, respirable dust particles before they disperse. Shop vacs clog quickly when used on fine dust; when the filter clogs, vacuum pressure drops, and more dust escapes into the air. Dust extractors include self-cleaning or pulse-clean mechanisms that shake accumulated fine dust off the filter. This leads to consistent pressure levels, and extends filter life. A shop vac is meant for short-term cleanup. Dust extractors are designed for longer periods of use, often with features like automatic tool-start functions, variable speed control, anti-static hoses, and spark-resistant motors for combustible dust safety. For operations covered under Cal/OSHA or Federal OSHA silica standards, or for controlling other hazardous respirable dusts like carbon, graphite, metals, wood, or asbestos, a simple shop vac with a HEPA filter is not sufficient. Hazardous materials require commercial-grade HEPA-filtered dust collection systems engineered and tested for fine particulate containment and exposure control.

Respirator cartridges for gas or vapor protection have a limited service life. They need to be changed before they become saturated and can no longer purify the air effectively. If an employer is using air-purifying respirators for protection against gases and vapors, Cal/OSHA T8 §5144(d)(3)(C) requires that the employer either: Use a cartridge with an end-of-service-life indicator (ESLI) that provides an indication to the user that the cartridge has reached the end of its service life. Unfortunately, ESLI cartridges are not available for most chemicals. Implement a time-based cartridge changeout schedule. This must be, per Cal/OSHA, “based on objective information or data that will ensure that ... cartridges are changed before the end of their service life. The employer shall describe in the respirator program the information and data relied upon and the basis for the ... cartridge change schedule.” Relying on users to detect the end of the cartridge service life by smell, taste, or irritation of the chemical passing through is not compliant as a primary method for cartridge changeout. It may be used only as a secondary safeguard to the employer's time-based changeout schedule. This is a common mistake: an employer identifies a potential respiratory hazard, buys respirators, and provides fit testing - yet skips the crucial step of a formal, documented hazard assessment and changeout schedule. For gas or vapor exposures, your written program should clearly specify: • The correct respirator type for the task • Appropriate cartridge or combination filter-cartridge • A time-based changeout schedule supported by data Safewest can help develop or review your respirator program, including hazard assessments and cartridge change schedules. Contact us to make sure your program is compliant and your employees are protected.

HAZWOPER (Hazardous Waste Operations and Emergency Response) training requirements apply to certain operations involving hazardous waste. These requirements dictate the amount, type and levels of training that employees working with hazardous waste must receive. The requirements for hazwoper training can be found in Cal/OSHA § 5192 and Federal 49 CFR 1910.120 . In general, there are three categories of hazmat operations, and specific training requirements for each. These three categories are hazmat site cleanup, emergency response, and operations at treatment, storage, and disposal (TSDF) facilities. Site Cleanup Cleanup and removal work at sites that have been identified by a government agency (state, federal, or local) as having an accumulation of hazardous substances that creates a threat to the health and safety of individuals or the environment or both. General site workers removing hazmat with potential exposure to hazardous substances and health hazards shall have 40 Hours of Training + 3 Days Supervised Field Experience. General site workers in areas where hazard levels have been fully identified, exposures are below published safety limits, there are no health hazards, no possibility of an emergency release, and respirators are not required shall have 24 hours of training + 1 day supervised field experience. Occasional/limited site workers (such as those doing monitoring or surveying) and are unlikely to be exposed to dangerous levels of hazmat shall have 24 hours of training + 1 day supervised field experience. Supervisors of general site workers shall meet the same training requirements as that category of general site worker, plus have an additional eight additional hours of specialized hazardous waste operations management training. All categories of site cleanup workers shall have 8 hours of annual refresher training. Emergency Response Emergency response to releases of, or substantial threats of releases of, hazardous substances, regardless of location. Awareness Level (FRA): Basic awareness, recognize hazmat threat, call for help. Competence based, no hourly requirement. Operations Level (FRO): Defensive response, contain and limit the release. 8 hours of training required (or a competence-based option exists for experienced workers). Hazmat Technicians and Hazmat Specialists: Direct response to stop a release of hazardous substances. Training scope and duties varies depending on position/role. 24 hours of training required. Incident Commander/Manager: Control and manage scene, implement response plans. 24 hours of training required. All emergency response workers shall receive annual refresher training or evaluation to demonstrate competency in their required areas. TSDF Operations Operations at Hazardous Waste Treatment, Storage, and Disposal Facilities (TSDFs) Workers are required to have 24 hours of initial training, and 8 hours annual refresher training.

The most important thing to know about snakebites is that people drastically overestimate both the likelihood and the severity of venomous snake bites in the US. Snakebites are fairly rare, and fatalities from snakebites are so unlikely (generally 5-10 per year in the entire country), a person is many times more likely to die from a lightning strike, or a heat-related emergency, or any number of other outdoor hazards. Prevention is simple. It is relatively simple to avoid most snakebites by being aware of where you step, not reaching or climbing on any area you haven't visually inspected first, and not approaching snakes to catch, kill, or photograph them. There are some significant misunderstandings about first aid measures for snake bites, many unfortunately perpetuated by uninformed first aid instructors and irresponsible equipment vendors. Do NOT apply suction. Avoid the use of commercial snakebite kits with suction pumps, like the Sawyer Extractor. See our article on venom extractors for more information on these ineffective and dangerous devices. Do NOT apply tourniquets or constricting bands. Do NOT cut the skin. Basic first aid measures are simple. Here's what you should do: Keep the person calm and avoid unnecessary movement. Why: Keeping the person's heartrate in a normal range slows the distribution of venom in their body. Remove watches, rings, and other tight fitting items. Why: These can constrict bloodflow if the person's limbs start to swell due to the venom. Call 911. If you do not have cellphone service, you will have to consider either finding a way to transport the person, or leaving them while you try to reach an area with cellphone service. Why: The only definitive care for a venomous snakebite is transport to a hospital for supportive care, and possibly anti-venom medication. For people working (or recreating) outdoors, mindfulness of where you place your feet and hands is your best defense against snakebites. If you will be in an area without cellphone coverage, investing in a means of emergency communication such as a satellite phone or messenger, personal locator beacon, two-way radio is the most important part of your emergency response plan. Three action steps for California employers: Review this information with your workers in April or March, which is when snake sightings will begin to increase. Ensure workplace first aid supplies do not contain outdated and dangerous supplies like snakebite kits and venom extractors. Ensure workers in remote areas have adequate means of emergency communications.

Cal/OSHA's requirements for workplace respiratory protection can be found in 8 CCR §5144 . Violations of the respiratory protection standard are one of the top 10 most frequently cited violations by Cal/OSHA, and a high-priority enforcement area. Any employer whose employees are required to use respirators must develop a written respiratory protection program and provide employees with medical evaluations, respirator training, and fit testing before they use respirators at work. This article summarizes these regulatory requirements and explains why they are important. Written Program Why: Trying to run a respirator program without a written plan is like building a house without blueprints. Work will happen, but not in a consistent, reliable, or compliant way. Your written program must be customized to your workplace. It should specify which positions or tasks require respirator use, what types of NIOSH-approved respirators are to be used, and how your company will provide required medical evaluations, fit testing, and training for your employees. The program should also describe procedures for respirator use and maintenance, ongoing program evaluation, and who is responsible for overseeing the respirator program. Cal/OSHA §5144(c): "The employer shall ... develop and implement a written respiratory protection program with required worksite-specific procedures and elements for required respirator use. The program must be administered by a suitably trained program administrator." Medical Evaluation Why: Respirator use puts greater stress on the worker’s body, especially the heart and lungs. A medical evaluation helps rule out any serious health problems that could be worsened by respirator use. Before wearing a respirator at work, employees must complete a health history questionnaire that is evaluated by a healthcare provider, who then determines whether the employee is approved to wear a respirator or if additional evaluation (such as a physical exam or pulmonary function test) is required. Cal/OSHA §5144(e): "The employer shall provide a medical evaluation to determine the employee's ability to use a respirator, before the employee is fit tested or required to use the respirator in the workplace." Employee Training Why: Workers need to know how the respirator works, how to use it correctly in the workplace, and what problems to watch out for. Employees should receive training on the capabilities and limitations of the respirator, what tasks they should use the respirator for, how to inspect, put on, remove, and use the mask, procedures for maintenance (if applicable) and storage, identifying and troubleshooting problems, and the general requirements of the OSHA standard. Cal/OSHA §5144(k): "The employer shall ... provide effective training to employees who are required to use respirators. The training must be comprehensive, understandable, and recur annually, and more often if necessary." Fit Testing Why: Every person's body is different, and employees need to make sure they are wearing a respirator that makes an adequate seal to their face. Employees should be fit tested to identify the specific make, model, style, and size of the respirator that is best suited for each employee, and check for problems with respirator condition, use, and donning procedure. Cal/OSHA §5144(f): "...before an employee may be required to use any respirator with a negative or positive pressure tight-fitting facepiece, the employee must be fit tested with the same make, model, style, and size of respirator that will be used." Together, the written program, medical evaluations, employee training, and fit testing form the core of an OSHA-compliant workplace respirator program. Safewest can assist employers with all required elements of a respiratory protection program. If you need help, or just want a few questions answered, contact us for a free consultation.

OSHA’s respiratory protection standard leaves no ambiguity: tight-fitting respirators cannot be used with facial hair in the seal area of the facepiece. Non-compliance remains common, creating unnecessary risk to employee health, and exposing employers to OSHA penalties for worker noncompliance. What follows is a summary of the relevant regulations and guidance:

When inspecting fire extinguishers, some people (including a troubling number of safety professionals and extinguisher training instructors) think that it is necessary to shake, tap, or invert the extinguisher contents to keep them properly mixed, or prevent them from solidifying. However, this is not only unnecessary but also potentially unsafe, and can damage the extinguisher. The myth of needing to shake or invert extinguishers is so common, Amerex, the world's largest manufacturer of fire extinguishers, has had to release a notice telling people NOT to do this because it can damage the extinguisher. Dry chemical extinguishers are essentially a pressurized cylinder containing a powder extinguishing agent, which is released when the extinguisher is activated. Modern extinguishers are designed and tested so that the extinguishing agent is distributed evenly and remains effective even when the extinguisher is stored for long periods. Shaking or inverting the extinguisher can damage the internal parts of the extinguisher, including the gauge and pressure valve. This can reduce the extinguisher’s effectiveness or even cause it to malfunction when needed. Extinguishers are also heavy, and difficult to grip when shaking or inverting. There is the risk that the person inspecting the extinguisher may accidentally drop it, injuring themselves or damaging the extinguisher. Avoid this safety "worst practice" and instead focus on the essentials of a good extinguisher inspection: Look for Physical Damage: Check the extinguisher body, valve, nozzle, and hose for any signs of damage or corrosion. Check the Pressure Gauge: If the extinguisher has a gauge, verify that the needle is in the green zone, indicating that the extinguisher is properly pressurized. Inspect the Pin and Seal: Verify that the safety pin and plastic seal are intact, ensuring the extinguisher hasn’t been used or tampered with. By following these steps, you ensure that the extinguisher remains in good working order without the risk of damaging it or injuring yourself by shaking, taping, or turning it upside down. Proper inspection, handling and storage are key to ensuring that a fire extinguisher is ready when you need it most.

Safewest uses a quantitative fit test (QNFT) method for all respirator types, as it’s the standard for objectively and accurately assessing respirator fit using specialized air measurement equipment. The alternative, a qualitative fit test (QLFT), relies on spraying a chemical at the user while they are wearing their respirator. If the user detects the chemical, the respirator has a leak. If they don't, the respirator is assumed to have an adequate seal. The amount of chemical sprayed and the sequence used is important, and this fit test method is often done incorrectly by inexperienced and insufficiently trained fit test providers. Qualitative fit testing (QLFT) is done by companies that cannot or do not want to make the investment in quantitative fit test (QNFT) equipment, which generally costs between $15,000 and $18,000 per machine. One problem with qualitative fit tests (QLFT) is that they are less accurate. For this reason, this method generally cannot be used for fit testing full face respirators; OSHA requires a quantitative fit test (QNFT) for these respirator types, unless their use is in a lower-contamination scenario where a half-face respirator would also have been appropriate. Another problem with qualitative fit testing (QLFT) is that the chemical sprayed at the respirator user can cause health problems. There are a few different chemicals used for this type of fit testing, and one of the most popular, and the most dangerous, is called "irritant smoke." This fit test method relies on spraying a hazardous chemical called hydrogen chloride towards the employee’s face while they are wearing the respirator; if this chemical irritates their eyes, nose, and lungs, this indicates the respirator is leaking. It’s a less accurate, dangerous, and error-prone method which NIOSH strongly recommends not ever be used. NIOSH is the Federal agency that conducts research on occupational safety and health. One of their purposes is to give scientific and technical advice to OSHA on regulations. In a published policy statement(1), they said the following: "NIOSH, in its formal comments to OSHA [on fit testing methods]..strongly recommended against the use of this fit test method because of the health risk associated with exposure to the irritant smoke [and] NIOSH continues to recommend against the use of irritant smoke fit testing for these same reasons . . . Air sampling has shown that ventilation smoke tubes can produce highly variable and unpredictable hydrogen chloride concentrations far exceeding 5 ppm." The reason 5 ppm is emphasized is because by law (under the exposure limits established by OSHA), that is the maximum airborne concentration of hydrogen chloride that an employee can be exposed to. In other words, this common qualitative fit testing method can, ironically, expose employees to unsafe concentrations of a dangerous chemical, and violate OSHA regulations. If you are an employer on a budget conducting fit testing internally, avoid using irritant smoke, and select one of the alternative qualitative (QLFT) methods such as saccharin or Bitrex. If you are evaluating vendors to provide fit testing for your employees, we recommend selecting those that have made the appropriate investment in quantitative fit testing (QNFT) equipment. References: 1. NIOSH Respirator Use Policy Statement, August 4 1999 In: NIOSH policy statements. Cincinnati, OH: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health